High quality restorers of Concours winning Healeys, Road, Race and Rally.

Welcome with all of your enquires.

Front quarter view

- Loading

- Driving on to the trailer

- Owner collecting our most recent restoration

- First test drive

- Yours truly sampling the car for the last time

- Two gentlemen very pleased with the result

- A proud owner, to the right, and friend collect the car

- Completed and ready for delivery

- Interior as close to original as possible with the materials of today

- The place to be

- Interior custom made by us and for us

- I wish it was mine!

- What a great profile

- Beautiful and drives like a charm

- Engine detailed according to American concours standards

- Mildly tuned engine.

- The complete interior

- Great color combination

- Our latest and without doubt greatest restoration

- Very rare nos trafficator for non-adjustable steering wheel

- K&N air filters, since current repros are not really up for the work

- A real beauty

- Correct in every detail

- Full concours detailing

- Full aluminium body with perfect fit

- All systems go!

- Test driving gave no unpleasant surprises

- Rear quarter view, always impressive

- Badge

- It looks like a dream but more important drives like one

- Front quarter view

- Almost finished!

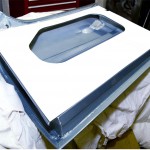

- Bonnet with a fit second to none

- Bonnet grille and top cowl

- Ash tray

- Door catch finisher plate

- Nos windscreen washer pump. Works well as opposed to reproductions

- Boot lid fits just as it should

- Factory fit after a lot of work on our part.

- Aluminium door that fits perfectly.

- Vacuum advance pipe

- Interior door handle. The door shuts and opens with the “Mercedes Benz feel”

- Interior custom made by us to correct original specs

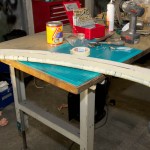

- Work in progress

- Correctly detailed boot. Solid rivets at rear skirt.

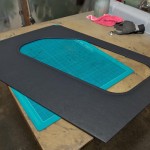

- Custom made door panels. Much better than prefabricated.

- Perfect body panel fit

- Perfect fit of the hood and perfect door shut lines

- Sidescreen mounted

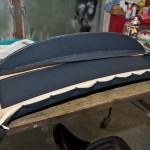

- Hood finished

- Distributor mounted to the engine

- Distributor refurbished with all nos Lucas parts

- Nos sparkplug lead and nos distributor cap

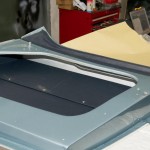

- Original hood frame

- Loop made of webbing

- Tonneau cover with Tenax fasteners

- Tonneau cover fitted

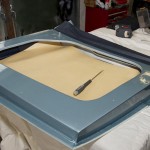

- Next the Everflex shall be folded over the header rail

- Almost finished

- Rear finished

- Header rail in place but work begins at the rear

- This hood doesn´t fit very well. Something has to be done.

- Completed header rail

- Upholstering the header rail

- Car with complete interior

- Completed seats

- Completed interior

- Seat back

- Seat cover sewn in England according to our correct template.

- Glueing seat covers

- Waiting for the cover

- Doing the foam and padding

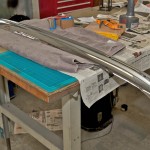

- Rechromed bumper with aluminium front valance

- Rechromed original bumper fitted

- Windscreen on the car. It worked despite bad rubber seal

- Rechromed original Eversure rear view mirror

- Engine compartment near completion

- Door panel and anodized cockpit moulding

- Passenger door

- Door installed and painted

- Boot lid installed

- All aluminium body

- Looking good

- New rubber seal pops out and thus needs to be glued. -Not good!

- Exterior door handle and door lock

- Aluminium door

- Door panel fitted

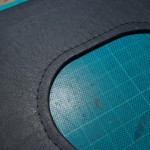

- Trimming leather cloth

- Glueing leather cloth

- Door liners fitted

- Door being assembled

- Painted door

- Instruments

- Instruments in place and hooked up

- Horn mounted in its place

- Horn

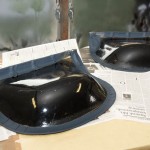

- Horns completed and painted in the correct color

- Original choke wire with locking mechanism

- Back side of instruments

- Expertly restored instruments

- Completed rear seat area

- Wooden block for draught excluder in place

- Anodized aluminium cockpit mouldings

- Wooden block

- Dressing up wooden block for draught excluder

- Completed seat pans in place

- Completed front sides

- Completed back sides

- Stitched in place

- Stitching rear seat cover to pan

- Remove foam that for some reason is stitched to the back of the leather

- Oil filter assembly

- Cushions completed

- Seat frames completed

- Seat frames to be upholstered with leather cloth

- Pleated area of seat cover glued to foam

- Fabric glued to the middle part for reinforcement

- Foams secured to the pans with some thin fabric

- Foams glued to seat pans

- Seat foams “drilled” in order to make them softer

- Finished seat back

- Finished seat back

- Upholstering the rear seat back

- Head lamps and indicators in place

- Changing the head light harness to original type

- Rechromed original bumper

- Boot nearly there

- Original battery cable

- Reflector and indicator

- Original battery master switch and bracket

- Changing the knob to correct short original type

- Draught excluder and sill cover

- Original SU fuel pump

- Restored original Smiths fuel sending unit

- Fuel tank

- Quarter panel installed and completed

- Carpet set made in England to our spec. Much better than any prefabricated set.

- Cushion on transmission tunnel stitched in place

- Masking before painting Old English White

- Interior well on the way

- Stitching makes the final touch

- Completed door panel

- Under side

- Under side

- Bleeding the brakes and the clutch

- Refurbished starter armature

- Starter armature

- Hood frame

- Milling angled shims for door lock

- Hood frame

- Trial fitting of doors before painting OEW

- Rolling the car for calibration of speedo

- Routing of pipes and cables

- Lucas helmet battery terminal and cotton covered battery cable

- Stitched door liner panel

- Trial fitted rear quarter panel

- Back side

- Finished quarter panel

- Glueing leather cloth to rear quarter panel

- Countersunk rivet on rear quarter panel

- Finished backside

- Glueing backside leather cloth

- Cutting backside leather cloth

- Backside

- Finished front sides

- Trimmed cotton wadding

- Cotton wadding glued in place

- Fitting the trim screws

- Bending the rear quarter panels

- Making rear quarter panels

- Front suspension complete

- Capillary tubing in place

- Dual gauge and blanking plug for some Swedish cars

- Dual gauge

- Heater pipe and attaching hardware

- Heater pipe

- Blanking plug for starter button aperture

- Heater pipe and attaching hardware

- Primary aligment of front wheels

- Rechromed original bumper

- Rubber seal and dashtop with piping

- Dashtop with all hardware installed

- Dashtop in place

- White piping

- Flip side

- Leathercloth as original

- Rubber seal attached with split rivets

- Wadding is glued to the wood

- Rubber foam glued to the wood

- Rubber foam taped in place while glue cures

- Fitting the hardware

- Fitting the panel before upholstery

- The finished product

- Leathercloth

- Parcel shelf

- Leathercloth on door liners

- New door liners

- Door liner panels being fitted

- Template for door panel

- Dash top wood being made

- Templates for rear quarter panels

- Dash top wood being fitted

- Making of rear quarter panels

- Tubular exhaust with heat wrap

- Duo tone

- Ice Blue Metallic over Old English White

- Fitting of the gearbox tunnel

- Primed horns

- Back side HF 1748

- Restoring Lucas HF 1748 Horns

- HF 1748 horn

- Presssure testing rerouted front tubular exhaust manifold

- Fitting tubular exhaust manifold

- Rerouting manifold

- New pieces butwelded to manifold

- Cut manifold

- Installed gearbox

- Installed engine

- Engine in place

- Girling ckutch slave cylinder

- Shut pillar

- Badge

- Grille and Austin Healey badge

- Grille installed

- Grille aperture with lower grille lip

- Heater fan housing and ducts

- Collapsible steering and fresh air duct

- Car waiting for drivetrain to be installed

- Heater and dash

- Dash and steering lock

- Heater in place

- Collapsible steering column

- Dashboard in place

- Dashboard dressed up

- Heater completed

- Heater being assembled

- Steering column with nos lock

- Provision for lock on new column

- New steering column

- Nos steering wheel lock as supplied to some Swedish cars

- For steering wheel lock

- Original steering column with provision for lock

- Engine compartment

- Engine compartment

- Rear axle

- Painted wings

- Front suspension

- Rear inner hub

- Engine compartment

- Fitting the dashboard

- Refurbished underside

- Solid rivets as original at rear skirt

- Back to the shop for assembly

- Looks good

- Healey Ice Blue Metallic

- Primed and sealed seams

- Chassis mounted in “roaster” prior to painting

- Chassis shotblasted prior to painting

- Aluminium body

- Pressing in the overdrive oil pump

- Restored gearbox

- Overdrive disassembled

- Rear seat area

- Chassis and aluminium body taking shape

- Body work on the way

- Disassembled gearbox

- Gearbox and overdrive parted

- Disassembling gearbox

- Checking engine tolerances with plastelina

- Reconditioned and gas flowed head

- Body work with simple jig for aligment of front lights

- Adjusting the camshaft

- Assembled block

- Assembled block with milled valve pockets

- Painted with correct engine color derived from spectrometer test

- Block ready for painting

- Valve pockets about to be milled

- Sheet metal work

- Checking the sizes of the crank

- Disassembly of engine

- Beautiful aluminium body panels

- Bare chassis

- All paint and filler ground off front shroud

- A lot of work ahead

- Starting disassembly