The car is in a surprisingly good shape, despite its looks

I would like to thank the following people whose help so far with this very special project have been invaluable:

Roger Moment in Colorado.

For delivering many special made original parts and willingly offer very good advise from his vast knowledge of these cars

Steve Norton in the UK.

For delivering many parts made of unobtanium and offering his very good services

Anders Pettersson in Sweden.

For his generosity in sharing hard to find parts with me, his moral support and for being a great buddy

Lars Törnblad in Sweden

For his great knowledge of all things technical and every other subject you could think of for that matter. Lars has played a vital role in all of my restorations. Without his help and support my restorations would never have been able to achieve the same levels. A true scholar, a gentleman and very generous

Hasse Syrén in Sweden

For making high class metal work and for being humble, generous and very friendly

Andy Scheffel in Switzerland

For making an artform out of the business of restoring automotive instruments

Ola Grahm in Sweden

For helping me run this website and for being a good and loyal friend

Janne Holmkvist in Sweden

For helping me produce first class upholstery

The owner

For being patient and understanding with all of the complications and set backs that surface in a project like this and for his general enthusiasm and support

All people sending me e-mails and making comments on Facebook

For being very supportive and appreciative

Magazine kindly donated by Anders Pettersson in Gothenburg, who is a well known Swedish Healey enthusiast and collector. Vintage photos of the car with it´s first owner Raymond Sjöqvist courtesy of Ulf Håkansson in Halmstad, who is a well known Swedish Healey enthusiast and historian. Photos from the eighties courtesy of Henrik Engström.

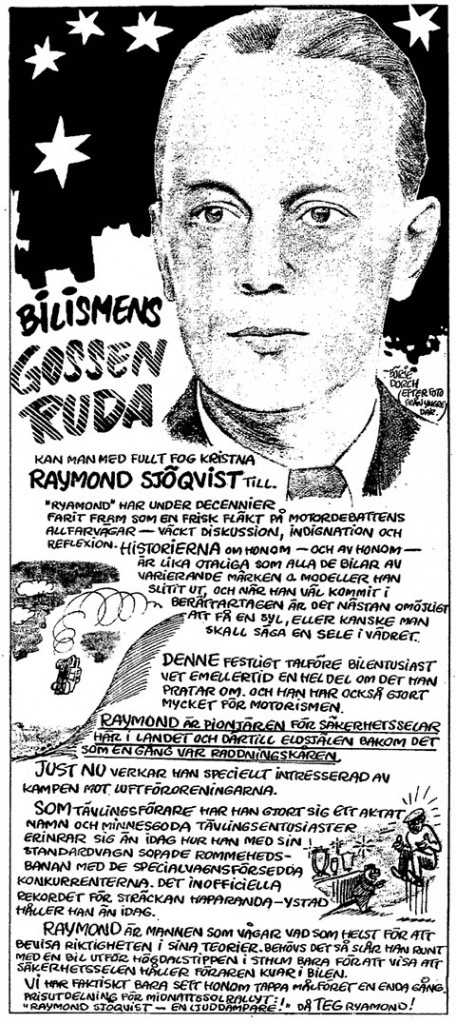

A caricature about the first owner, Raymond Sjöqvist. By well known Swedish cartoonist and columnist Börje Dorch. Courtesy of the first owners son Per-Raymond Sjöqvist.

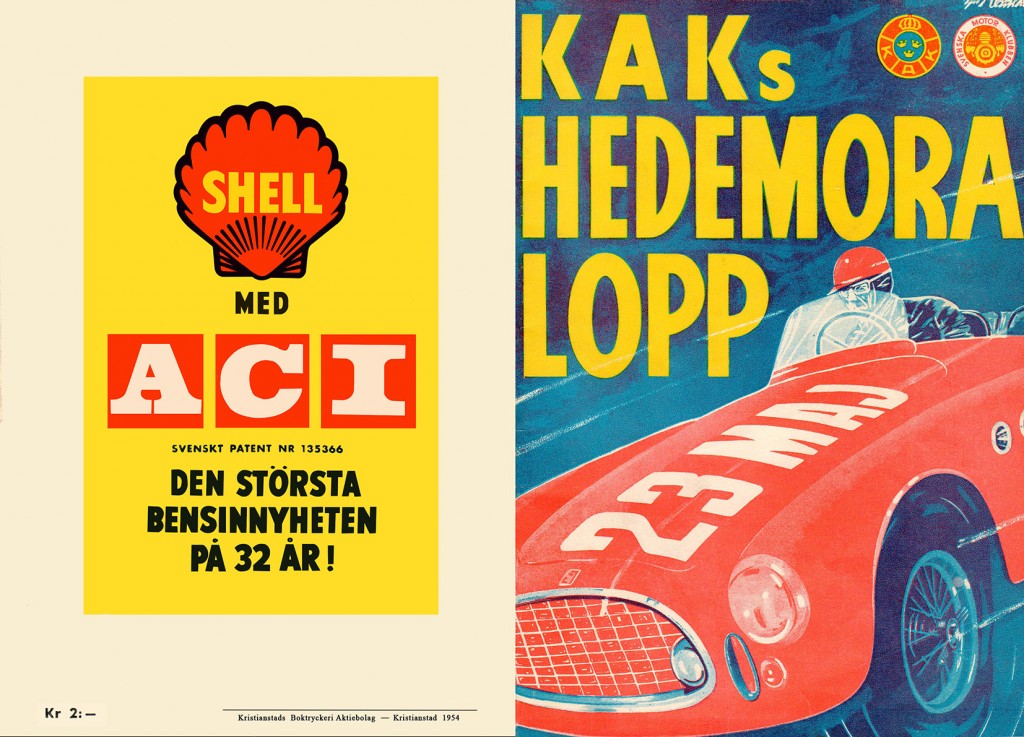

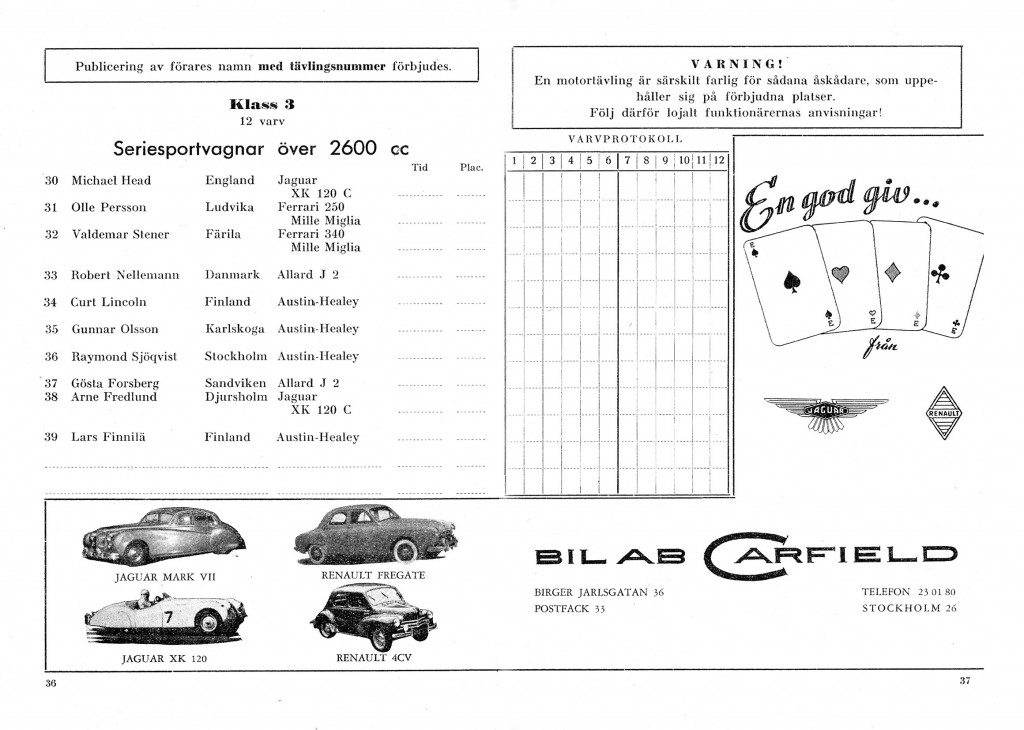

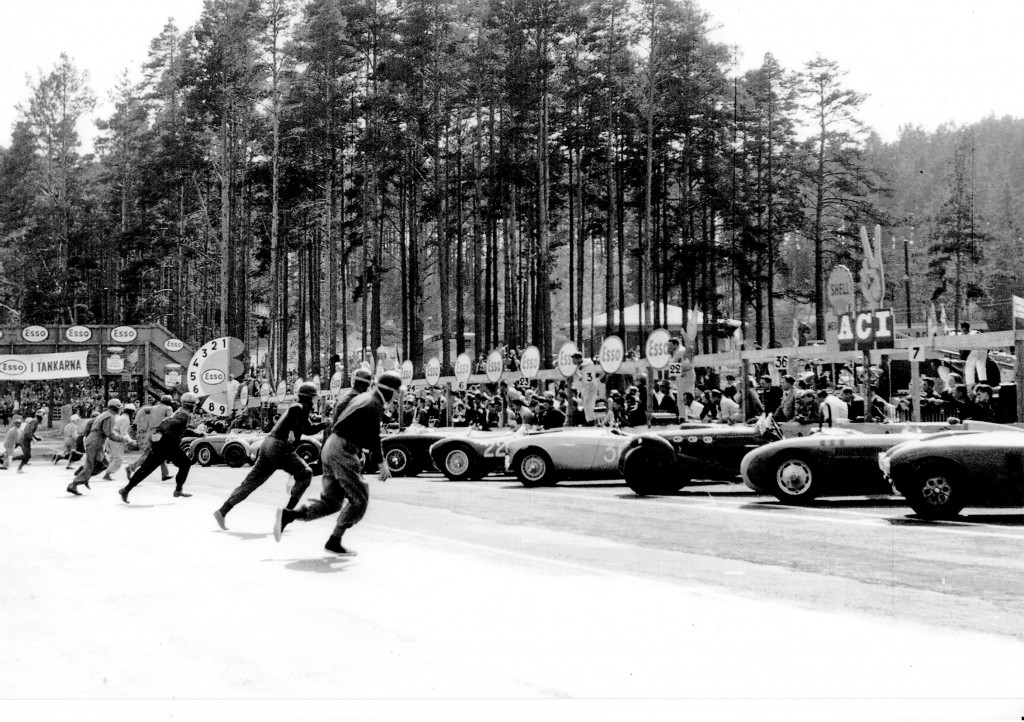

Hedemora 1954, Race Program

Starting list

Le Mans start at Hedemora in -54

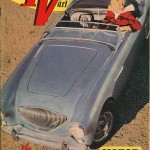

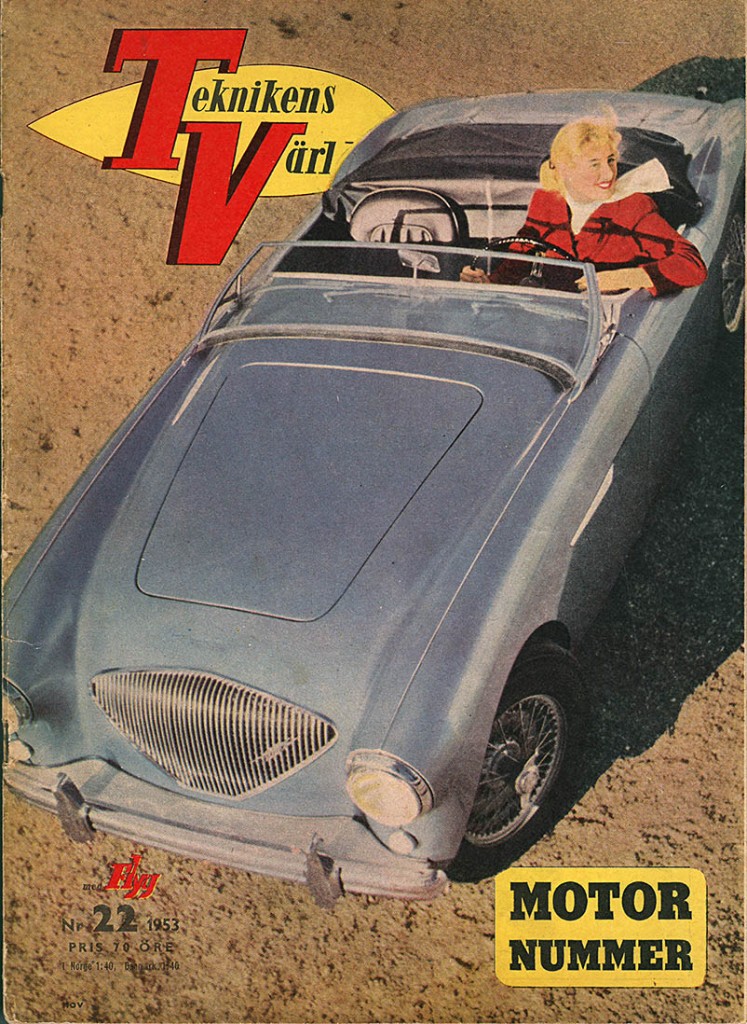

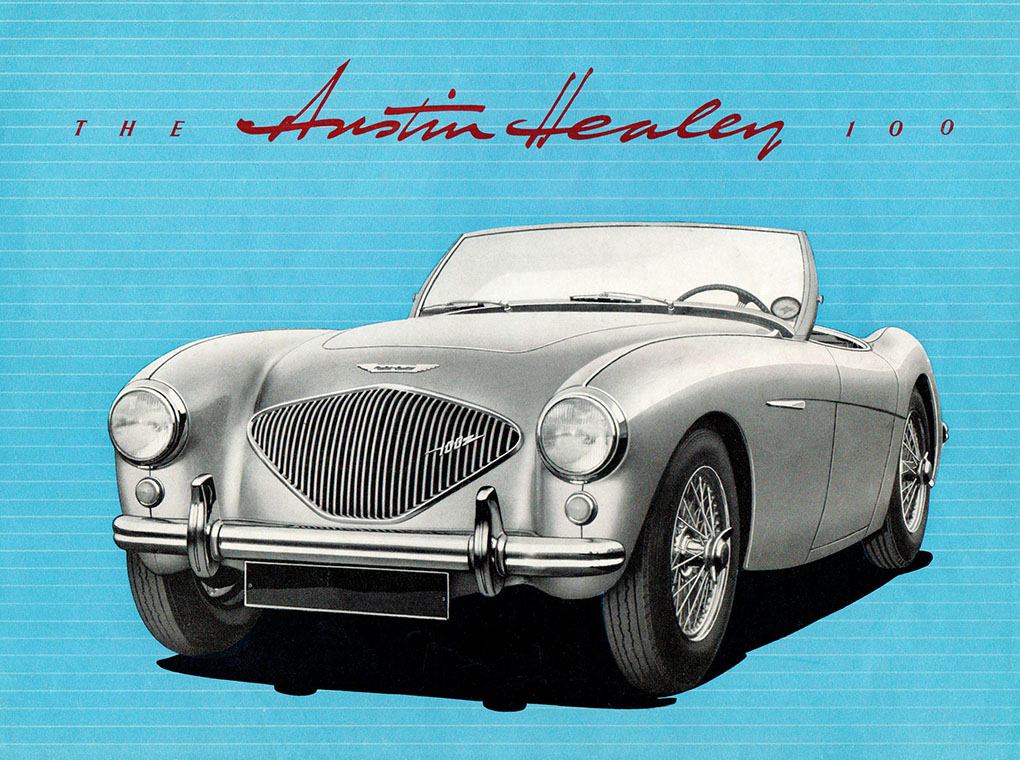

Front page of Teknikens Värld no 22 1953 kindly donated to us by Anders Pettersson

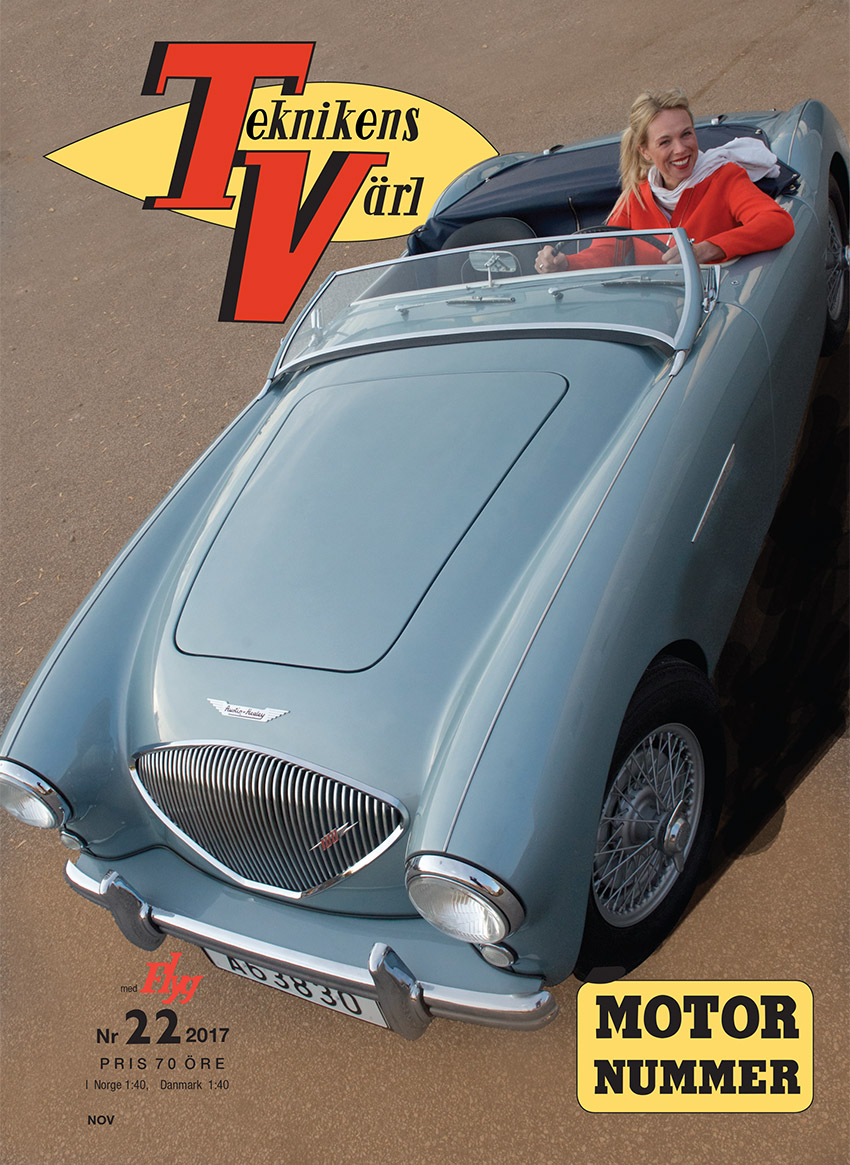

The same car 64 years later on a cover inspired by the original.

Motor Revy #1 Dec 1953

Skarpnäcksloppet 1953. Raymond Sjöqvist and Roberto Rosselini amongst others. Clip from Aftonbladet.

Article from Swedish tabloid Expressen. October 14 1956. Courtesy of Ulf Håkansson

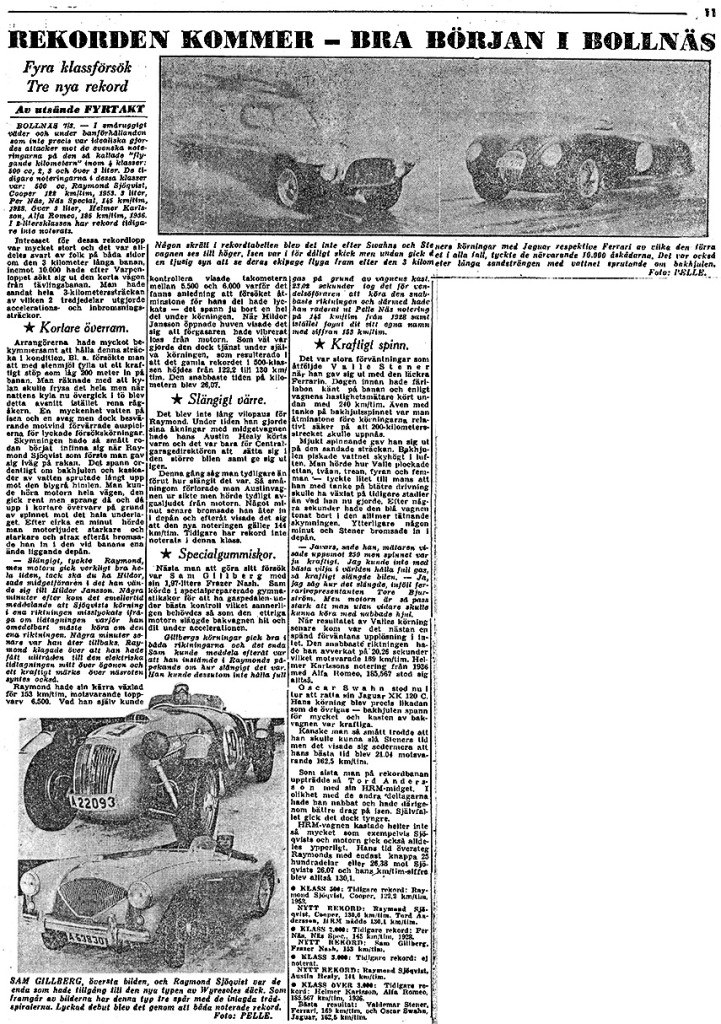

Record breaking on ice. Article from -54.

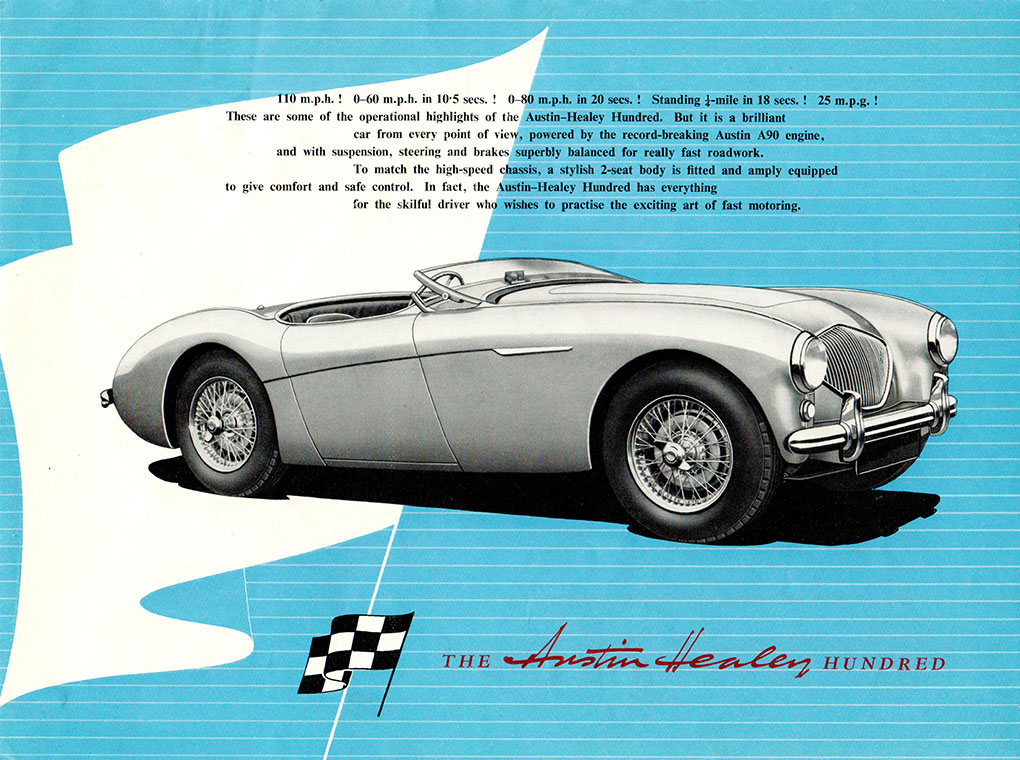

Early 1953 brochure, page 1.

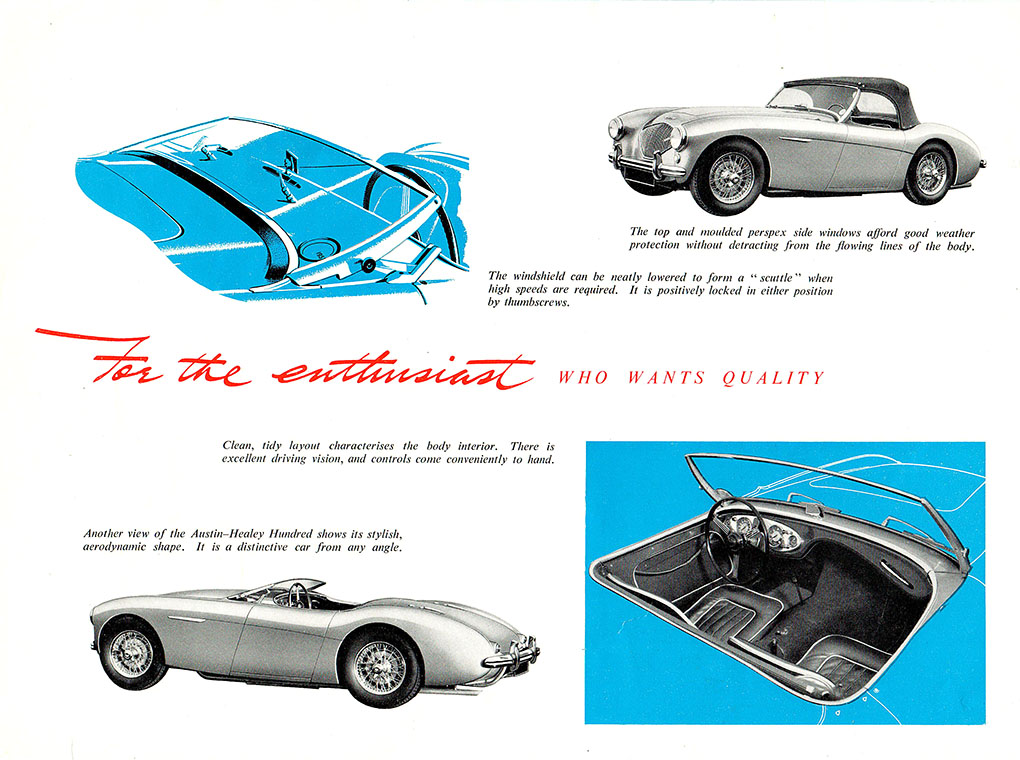

Early brochure, page 2

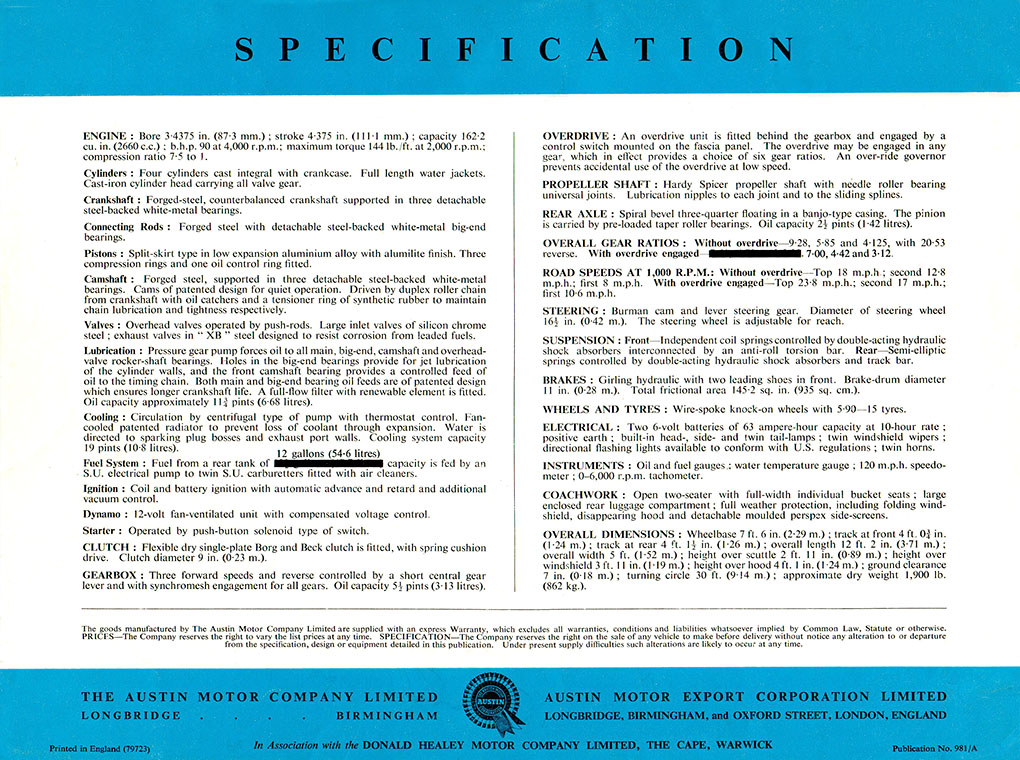

Early brochure, page 3

Early brochure, page 4

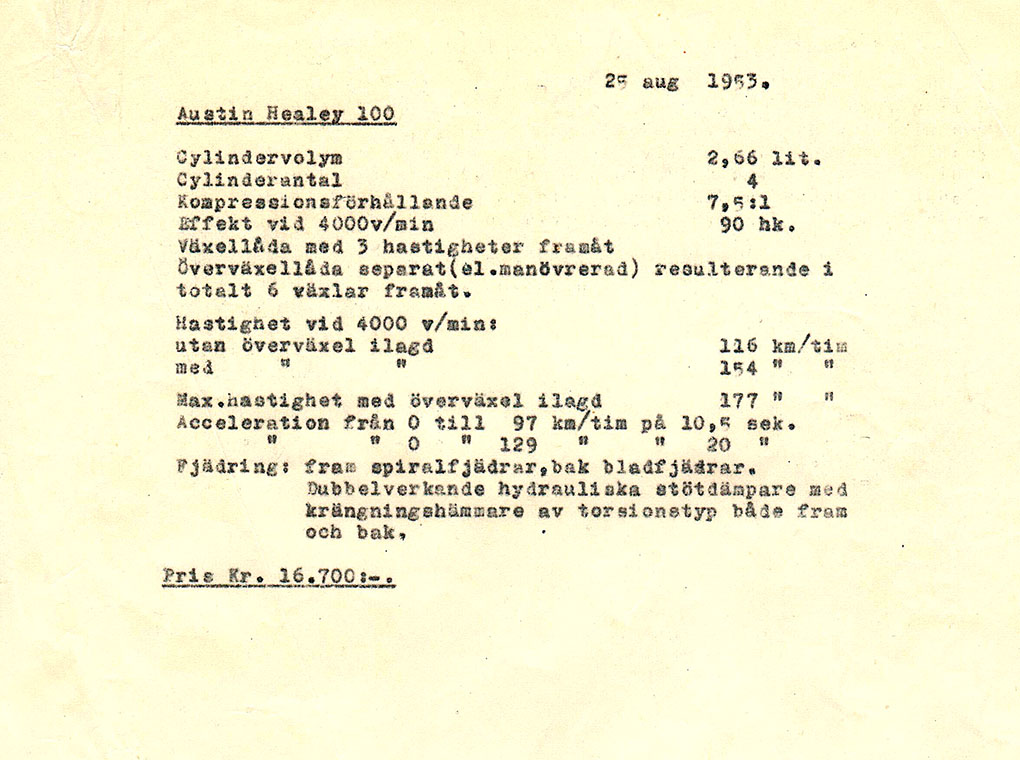

Swedish dealer specification, accompanying the brochure

- On the way to its owner

- Correct August 1953 Triple X etching

- Rare early sidescreens

- Rare early sidescreens

- Rare early side sidescreens

- Completed interior

- Completed interior

- Finisher plate door catch

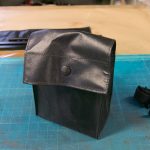

- Jack handle bag made by Roger Moment

- Jack handles

- Jack bag

- Jack bag made by Roger Moment

- Tool roll

- Tool roll made by Roger Moment. All original tools

- Correct radius coolant hose from Roger Moment. Also correct hose clamp or perhaps band

- The finished engine compartment

- Correct control box tag

- Correct front valance fasteners and o-ring around flasher/side light

- Dunlop RS5 on 48 spokes

- Custom made cover for the hood latch

- Custom made cover for the hood latch

- Checking the electricity

- Horns connected

- Beautifully restored by YesterYear Steering Wheels Australia

- Nos trafficator and restored original steering wheel

- Early adjustable upper stator tube

- New wiring harness

- Nos trafficator

- Early Bluemels adjustable steering wheel

- Early adjustable locking nut

- Dust spring collar, early type

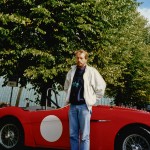

- Yours truly

- Starting up the engine for the first time

- Per-Raymond Sjöqvist, son of the first owner and the first passenger in the car

- Per-Raymond in the racing overall his father used in the Healey, talking to Healey historian Ulf Håkansson. Per-Raymond very kindly gifted the overall to the present owner

- Two Tenax studs on early cars. Note the small leather washer underneath each stud

- Cockpit mouldings reanodized in Poland

- Finished tonneau except for the small steering wheel pocket which has to be done after fitting to the car

- Finished bar pocket

- Vertical seams act as stop for bar

- Trimming the edging back side

- The edging is in place, ready to fold over the edge and be sewn once more

- Opening for rear view mirror stem is a tricky part to sew

- Rear attachment bar aperture trimmed

- Sewing the French Roll edging

- Zipper flip side

- Zipper in place. Nickel plated as original

- Folding and sewing the last couple of zipper seams

- First seams for zipper finished

- Stitching the zipper

- Preparing to sew in the zipper

- Edging material about 6 meters long

- Back side edges trimmed and cutting material for French Roll outer edging

- Trimming the back side edge

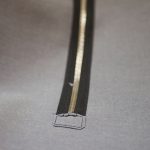

- Attachment bar made to Peter Svilans pattern

- Apertures for rear attachment points

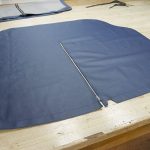

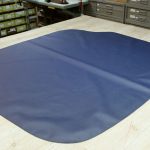

- Peter Svilans in Canada sent me this very elaborate pattern for an early Tonneau Cover. It was very generous of Mr Svilans and without his help we could never have made an original one

- Original shape early Tonneau Cover.

- Quite satisfactory fit

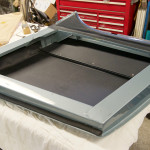

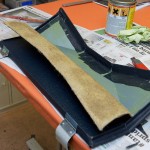

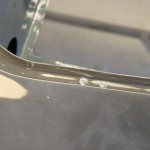

- The hood frame had to be realigned and the plexiglass extensively reshaped

- Fitting the sidescreens with the plexiglass

- Interior view with early way of attaching webbings

- Small screws hold the webbing on the inside

- Rear view

- Front view

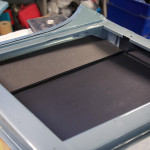

- Finished product

- No wrinkles

- Stapling the hidem strip

- Fitting the front with the correct webbing

- Stretching the rear

- Starting to fit the rear

- Stretching the front

- Robbins top from the US. Fits better than most others

- Starting to fit the hood. Made by Robbins and delivered by George Baxter in the US. -Thanks George!

- Header rail

- Ready to be sewn in

- Opening the seams

- Robbins hood came with semi stiff plastic sheets sewn in instead of these correct aluminium tabs

- Finished tabs.

- Aluminium tabs that sits inside hood front inner flaps. Pattern courtesy of Roger Moment.

- Hood frame incorrectly aligned

- Hood frame incorrectly aligned

- Early type brackets

- Early type sidescreen frame

- Early type sidescreen fitted. Chromed triangle holds the header rail against windscreen frame

- Sidescreen plexiglass

- Sidescreen chrome frame fitted

- Early frame repainted

- Restored and reriveted original early frame

- Boot lid original telescopic prop rod

- Boot lid fitted

- Cold air box with trial fitted trunking

- Bonnet lock

- Front bumper and apron

- Instruments are works of art

- Instruments expertly renovated by Andys Healey team

- Folded windscreen

- Windscreen in place

- Rims in place

- Headlamps in place

- Lucas European light units

- Fuel pump connected

- Battery master switch connected

- Connecting cable in place

- Newly made cotton covered battery connecting cable with terminals from Roger Moment

- Master switch

- Nos information tag

- Nos battery master switch

- Nos ground terminal and cable. Negative terminal made and supplied by Roger Moment

- Soon to be finished

- Clamps by Kilmartin supplied by Bart van Tiggelen

- Correct heater hose clamp

- Correct heater hose clamps, made by Kilmartin Australia courtesy of Bart van Tiggelen

- Engine with ancillaries

- Trial fitting of air trunking for cold air box

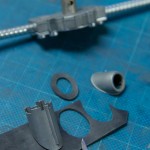

- Grommets for overflow pipes in cold airbox made by Roger Moment

- Nos distributor fitted. Wires in the new wiring loom too short for coil

- Original dynamo fitted

- Trial fitting of cold air box and overflow pipes

- Nos coil in place

- Nos coil with nos distributor in the background

- Nos Lucas coil

- Nos Lucas distributor cap

- Drive shaft attached to completed distributor

- Checking and adjusting distributor

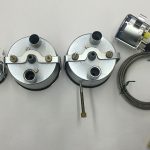

- Weights and new springs assembled

- Nos distributor and new 100M springs courtesy of Roger Moment

- Original starter motor cable and connectors

- Plastic fan used initially for safety reasons

- Nos glass and rim

- Nos glass and rim

- Original holder hooked up

- Tail light wiring and nos rubber body

- Tail light wiring

- Nos rubber body and original bulb holder

- Original bulb holders courtesy of Roger Moment

- End of fuel pipe painted in correct black

- Su fuel pump in place

- Changing to the correct SU fuel pump. Braided fuel hose came with the wrong threads in the male connectors

- Aligment is not satisfactory

- Attaching the levers in the correct position on the shafts

- Nos Su HS6

- H6

- Carbs in place

- Keeping the shaft aligned when tightening the carbs

- Original 100M intake manifold. Nos HS6 carbs

- Accelerator linkage

- Accelerator linkage

- Accelerator linkage rod, ball joints and spring bracket

- Second hand fuel pipe straightened

- Second hand fuel pipe cleaned

- Exhaust system painted

- Exhaust system completed

- Rear pipe close to the body

- Rear bracket in place

- It´s important to get the exhaust aligned with the lines of the car

- It´s important to get the exhaust as close to the floor as possible

- Custom bracket welded to pipe

- Custom made rear bracket

- Bracket with drill guides for correct fitment of the rubber mountings in the car

- Preparing to fit brackets

- Completed tig welds

- Welding around all tubes with everything attached in order to avoid distortion

- Ready for welding

- Using a spare head as a jig

- Spot welded for trying the fit

- Trying on the car

- Fitment has to be adjusted…

- 100 M style header

- NOS oil pressure hose

- Armrest

- Armrest fitted and holes for the seats punched into carpets

- Armrest

- Fixing the armrest

- Rear carpets fitted and edges bound

- Silver plated faces as original. Temperature gauge for open system. Works of art!

- Early set of instruments restored by Andy´s Healey team

- New carpets pieces stitched together and with a perfect fit.

- Restored by Andy´s Healey team and delivered with the instruments for the Healey

- An instrument for one of two remaining 1934 Citroen B7 Convertibles

- NOS revcounter cable

- Cockpit mouldings sanded smooth and waiting to be polished

- So we used the pieces for making a correct pattern

- The ribbing was not at a right angle

- Unfortunately the pieces were wrongly cut

- Fitting precut carpeting from England

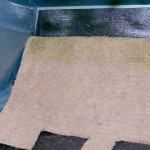

- Jute insulation

- Gearbox with wiring

- Clip for speedo cable and wiring harness

- NOS speedo and revcounter cables

- Quarter panel in place

- Rear quarter panels being trimmed

- Door panel in place.

- Cockpit mouldings being fitted. Next polishing and then anodizing.

- Cockpit mouldings being fitted

- Doors mounted.

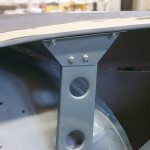

- Striker assembly mounted to door post.

- Complete early striker assembly.

- Bushing pressed into striker plate.

- Early striker plate. Made by Kilmartin.

- Door bracket for check mechanism. Original piece. Todays reproductions don´t come close.

- Door trimmings complete

- Trimming of door top completed. Folded edges.

- Trimming completed. Folded edges.

- Trimming upper part of door

- Fitting the doorpanel

- Finished door liner

- Gluing leather cloth

- Fitting doorliner

- Beading fitted

- Fitting aluminium trim piece

- Better lighting conditions

- Beautiful front end

- Calibration work for the speedo

- Out in the open

- Waiting for all of the ancillaries

- Highly tuned

- Engine in place

- The big lift

- Engine and trans

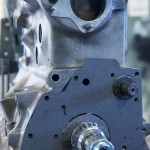

- Engine and transmission mated

- Uprated friction plate

- Eight bolted steel flywheel

- End plate

- Preparing for engine end plate

- Finishing the clutch pipe. Modification

- Fresh air trunking

- Fresh air trunking as close to original as possible. White thread had to be painted black

- Original rubber beading made by Roger Moment

- Complete

- Beading with tabs

- Front wing

- Wing in place

- Insulation between shroud and wing

- Door check

- Complete door check mechanism

- Assembling “brake” part

- Part of door check. Nos leaf springs are black

- All electrics hooked up. Waiting for the instruments

- Dashboard

- Original o/d switch

- 10-32 Truss head screws

- Truss head screw

- Inner wishbone pin in black

- Completed

- Front suspension right hand

- Front suspension completed

- Nos fulcrum nut

- Michael Salter reminded me that all fasteners in the suspension shall be black. Thanks!

- Black hardware and fasteners

- Changing all hardware and fasteners into black colour

- Nos Fulcrum nuts

- Body no plate in body colour

- Throttle switch linkage

- Throttle switch linkage

- Choke cable

- Choke cable

- Oil pressure pipe

- Oil pressure pipe

- Throttle linkage

- Throttle linkage rod

- Making oil pressure pipe

- Original plate borrowed from Anders Pettersson in Gothenburg

- Locking plate for steering box adjustment screw

- Nos handbrake cable

- Pedals

- Hydraulic clutch modification

- Various painted body parts

- Reservoir and transfer clear coated

- Various painted parts

- Engine ready for installation

- Painted head nut

- Dynamo and starter marked -53. Starter courtesy of Anders Pettersson, Gothenburg

- Painted head nuts

- Painted engine ancillaries

- Applied to reservoir

- Brake reservoir water transfer decal courtesy of Roger Moment

- Making a new fuel linkage lever

- Dashboard

- Cockpit side

- No clip for the fresh air wire on early 100´s

- Switch installed in the dash

- Original ignition switch and keys

- New wire and coil for fresh air cable

- Painted

- Bonnet lock pull

- Painted

- Original fresh air knob

- Finished phenolic washer

- Template for phenolic washer, which was discovered on early 100´s thanks to the research of Michael Salter

- Assembled dynamo

- Assembling painted dynamo

- Switches installed

- Grab handle wooden piece

- Assembled

- The same rubber strip as used on the bumper over riders

- Dashboard

- Finished seat

- Stapling beading around rear bottom edge

- Stapling beading around end

- Trimming leather

- Stapling leather onto wooden end on the second seat back

- Now on to the next seat

- The finished product

- Completed cushion

- Cover stapled in place to the base

- Cushion cover everted after the fluted area has been glued down to the foam

- The finished piece

- Backside with Hidem strip

- Bottom

- Finished end

- Hidem strip tacked into place

- Hand stitching the ends

- Front side.

- Backside

- Flip side

- Seatback end covered in leather

- Removing surplus material

- Cover being mounted

- Cover completed

- Stitching the outer beading

- Trying the finished fluted area for fit

- Stitching the beading

- Stitching the final flutes

- Trying the flutes

- Cutting the leather

- Prototype ready to test for fit and appearance

- Making prototype for backrest

- Prototype part of cushion cover

- Felt for the back

- Edge has been secured

- Securing the edge

- Trying the fit of the individual parts

- Tack panels and foam mounted to the seat back

- Making new tack panels

- Gluing foam into seat back.

- Foam have been shaped

- Gluing a missing piece to the foam

- Shaping foam

- Painting seatbases in correct black

- Shaping cushion foam

- Gluing additional foam on to sagging moulding

- Cutting away material from too thick cushion foam

- Beading around the door panel aperture was only used on early cars

- Stapling the beading

- Gluing the suede

- Gluing the vinyl

- Suede stitched to vinyl

- Gluing wadding to door panel plywood

- Door panel pattern in cardboard

- ID plate

- Footwell panels trim completed

- ID plate, courtesy of Bill Park in Canada, attached to footwell

- Footwell panel screwed to body

- Fotwell panel screw holes

- Plywood panels being lacquered

- Carpet

- Parcel tray

- Battery cable routed and attached to solenoid

- Solenoid terminal battery cable

- Battery cable being routed

- Battery in place

- Lucas Helmet terminal courtesy of Roger Moment

- Drilling the terminal

- Helicoil in place

- Inserting the helicoil

- Threaded to take a helicoil

- Tapping the threads

- Using another guide in order to tap the new threads straight.

- Drilling through the guide

- The threads for a pin bolt in the block got stripped. Using a dowel to center the drill guide correctly.

- Spare wheel and retaining hardware

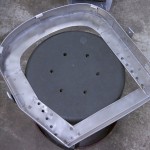

- Completed rear deck

- Spare wheel cover and battery lid

- Trimming of early type boot completed

- Flap

- Early type Armacord carpeting

- Everything in place

- Flaps sewn in place

- Flap

- All edges bound

- Trimming the bindings

- Stitching the edges, in correct French Roll fashion

- In complicated the binding has to be glued before stitching them

- Fuel tank piece

- Binding the edges

- Bound edge for filler tube

- Early type flap for tank carpet

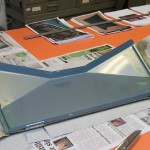

- Trying the fit of early type fuel tank carpet

- In place

- Gluing spring box pieces

- Almost there

- Gluing

- Spring box and boot floor carpet below. On top carpet for rear bulk head in cockpit

- Spare wheel cover in place

- Carpet for spring boxes and boot floor, early type

- Rear bulk head carpet in place

- Checking the fit of the finished cover

- Cutting the parts for the spare wheel cover

- Dummy spare wheel cover, made for checking the fit

- Rear wing carpets

- Rear wing carpets

- Spare wheel carpet

- Carpets ready for glueing

- Janne is stitching the binding for the rear inner wing piece

- Piece for rear bulk head in the boot

- Spare wheel stop trimmed

- Location of spare wheel stop

- Location of spare wheel stop

- Location of spare wheel stop

- Spare wheel stop

- Fitting the rear deck piece

- Vinyl cover in place

- Glued halfways

- Gluing the seam

- Marking the position for the seam in the vinyl cover

- Glued in place

- Inner wheel arch rear pieces

- Rear deck piece bound and ready to glue in place

- Carpet for rear shroud below the boot lid opening

- Finished product

- Inside Armacord being glued

- Battery lid

- Binding the edges on the big piece for the rear deck

- French roll bound edge and pieces stitched together

- Checking fit

- Checking fit of cut carpet piece

- Carpet ready to be cut after patterns

- Patterns that have been checked in the car

- Adjusting patterns in car

- Fitting trim patterns to the car

- Trying door and door check

- Trying door check strap with door in place. Unfortunately it has to be reshaped

- On its on wheels for the first time, since very long

- Front suspension completed

- Front spring

- Temporary wheel alignment

- Temporary wheel alignment

- Dunlop RS5 on 48 spoke wheel

- Front drum

- Front drum

- Riveted brake shoes

- Cylinders installed on brake back plate

- Wheel cylinders refurbished

- Original Girling wheel cylinders wit NOS repair kit

- Stub axle bearing spacer and shims

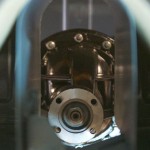

- Pressing bearing ring into front hub

- Greased

- Inner front wheel bearing

- Centre rod

- Original gaiter springs

- Correct rubber gaiter supplied by Roger Moment

- Side rod

- Ready for the boot

- Chasing threads

- Rear hub

- RH side drum

- Drum

- Riveted rear brake shoes

- Shaft in place

- Drive shafts

- Waiting for drive shaft

- LH nut on LH side

- RH nut on RH side

- Rear hubs ready for the rear axle

- Pressing in bearing

- New rear hub

- Piping and door seals

- Door pull cables beautifully refurbished by Steve Norton

- Spare wheel cover supplied by Steve

- Armrest supplied by Steve

- Second hide

- Beautiful blue hide supplied by Steve Norton

- Front wing temporarily fitted

- Looking good

- Front wing temporarily fitted in order to try the shape of the check strap

- Beading being put in place

- Protective tape on wing and shroud

- Use some tape on the tabs in order to protect the paint work

- Isolation between rear shroud and wing

- Hopefully the strap will be correct in shape. This will have to be tested with front wing and door in place

- The strap with it´s housing on the back attached. New screw holes has been drilled.

- On the backside of the centre hole the housing is attached. The screw holes for the housings were drilled in the wrong location and has therefore been welded.

- A pair of washers are needed in order not to squeeze the springs. The springs are too weak and there should be four.

- On the replicas the springs are squeezed when mounted.

- Fabricated door check straps with replica spring and roller housings for Triumph TR3

- Fabricated door check straps.

- Different door check assemblies. The upper left pair is wrongly sold as the earliest type up to body no 5000. Unfortunately completely wrong.

- Installed together with the correct demister trunking courtesy of Roger Moment

- Y-piece was found in Namibia of all places

- Heater unit. Finally with much sought after Y-piece

- Complete heater unit

- Brake adjuster

- Brake pipe by Doug Reid

- Nos rear brake hose

- Wheel cylinder

- Rear brake plate

- Temporary German made fuel pump

- Pedals and shaft in place

- Reaming pedal bracket

- Front carpets

- Pressure testing finished heater core

- Soldering correct long pipes

- Connections in place

- Pipe connection

- Making pipe connections

- Finally found a water tight heater core from a TR3

- Inner sill carpet glued in place

- Inner sill carpet glued in place

- Floor jute insulation

- Seat frames used to determine length of floor jute

- Footwell jute glued in place

- Footwell jute being glued

- Floor tar paper with seat attachment holes

- Seat attachment brackets seen from under side

- Seat attachment brackets seen from under side

- Seat attachment holes and brackets

- Seat attachment holes and brackets

- Early style seat attachment holes

- Drilling holes for seat attachments, early style

- Brackets on the way

- Making brackets for seat fasteners with the help of an image from the late Doug Reid

- Refurbished original starter button

- Mounted in heater casing

- Finished

- Using one nos and one original

- Making one correct heater rheostat switch

- Painted dull black

- Assembling master cylinder with new seals

- All seals had to be changed

- Nos Girling

- Nos brake master cylinder. Current repros are not reliable

- Nos brake master cylinder

- O/D relays hooked up. O/D harness will be changed into a correct cotton/cotton

- Original throttle switch and nos fuse block

- Nos voltage control box

- Firewall electrics

- Wiring hooked up

- Original starter solenoid

- Differential

- Nos shock link

- Nos shock link

- Front suspension

- Front suspension being assembled

- Wishbone arms and stub axle assembly

- Top trunnion, king pin and stub axle assembled

- Reaming finished, dust excluder installed

- Reaming bushings in stub axle

- Nos king pin

- Nos king pin set

- 100 grille badge

- Finally correct wrinkle finish

- Assembled

- Assembling idler

- Steering idler components

- It´s hard to find correct wrinkle finished paint

- Axle waiting for the diff

- Now the axle will locate properly again

- Filling the deformed hole with weld

- Straightening the plate

- Common error. Someone has tightened down the u-clamps securing the axle to the spring, without making sure that the hole lines up with the spring peg first

- Rear axle locating hole. RH undamaged

- Swedish made high quality spring with fiber washer

- Assembled

- Leaf spring

- Shackle pin and plate for rear spring

- Rear axle rebound rubber

- Correct fuel pipe elbow

- HF1748 rear view

- Installed

- Nos Lucas HF1748 wired up

- Rechromed original grille from Steve Norton

- Apron panel

- Dunlop crossplies

- Cold air valve in place

- Steering box in place

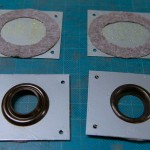

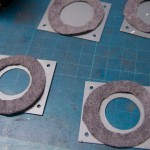

- RH blanking plate

- Inside plate and grommet

- Column and plate with grommet

- Steering column rubber grommets made by Roger Moment

- Felt seals

- Steering box seal courtesy of George Baxter US

- Rechromed original badge

- Completed

- Riveted

- Fresh air valve on firewall

- Finished

- Shelley jack

- Assembling early jack

- Wiper installed

- Wiper installed

- Wiper rack installed

- Wiper motor installed

- Nos wiper motor

- Cutting rubber seals for the wiper bezel

- Wiper wheelbox with rubber boot made by Roger Moment

- Foam rubber and original rubber bushes made by Roger Moment

- Mounting hardware for wiper motor

- Installed on the backside of the firewall

- Nos flasher unit

- Nos short stem as original

- Finished

- Finished

- Next comes the lid

- Order of reassembly

- Inside of switch

- Assembling one from two

- Switches taken apart

- “Nos” battery switch from eBay with burned off spring

- Two nos battery cut off switches

- Cleaned reassembled and water tight

- Heater water valve on engine head

- Reassembled with straightened anchor shaft. Marked -53

- Starter motor restored in England came back with bent anchor shaft. Straightening it

- Covered holes on R/H side

- Covers on R/H side

- Tar paper

- Tar paper

- Saving original striker plate bush for special early type

- Wiring going from front to rear

- Nos boot hinges from George Baxter in the US

- Installed on front right chassis leg

- Restoring chassis no plate

- Wiring on front cross member

- Holes filled up

- Repairing seat base

- Early seat base, handmade

- Early seat base

- Manual flip side

- Manual that came with the nos horns

- Special parts for a special car

- Nos Lucas HF1748 Horns

- Wiring

- Nos Lucas dimmer switch

- Painted dashboard

- Developed by Roger Moment and others in the US

- Installed

- Painted in the correct color

- Correctly shaped heat shield kit from the US

- Reassembly can commence

- Outstanding paint quality

- Back into the workshop

- Trailered from the paintshop

- Time for reassembly

- Very good paint job!

- Healey Grey, metallic variety as original

- Painted at last

- Gloss black

- Fuel tank in gloss black

- Ancillaries

- Engine

- Drums

- Starter

- Original paint recipe courtesy of the late Doug Reid

- Engine painted in original shade of green

- Miscellaneous parts and original jack

- Painted diff

- Painted front shocks

- Painted seat backs. If possible use the originals, since the repros available often are off in shape

- Radiator in primer

- Painted parts

- Painted steering box

- Brake back plates

- Primed

- Diff assembly waiting for paint

- Ready for paint

- Recored original radiator

- Repaired grease caps

- If possible, keep and repair original grease caps for front hubs. Modern repros don´t fit

- Engine no

- One very early and one little later seat back. Earliest one to the right

- Split rivets hold the plywood

- Back side of original foam

- Original foam markings

- Marking on early seat back

- On very early seat backs this shape was formed by the plywood

- Wadding on the back

- Original foam

- Original upholstery

- Factory work from -53

- Here´s how the factory did the upholstering

- Original seat cover. Painted in black at some point

- Masked prior to paint

- Masked prior to paint

- Core plugs in place

- Core plugs to be fitted

- Modification by previous owner

- Hubs to be partially painted in silver

- Nos dip switch

- Ready for paint

- Ready for paint

- Nos H6 carbs

- Rivets, front side

- Riveted

- Original rivets for bearing retaining plate

- Refurbishing dynamo

- Courtesy of Lasse Engwall

- Early instrument surround in as new condition

- Pulling rear shock link

- Repaired

- Worn rear brake plate

- Original headlamp bowl

- Redrilled

- Hole soldered

- Brake pedal lever

- repaired

- Additional hole

- Soon to be dismantled and painted

- Final sanding of body

- repaired

- Additional hole

- Repaired

- Worn bracket anti roll bar

- Repaired

- Worn Panhard rod bracket

- Repaired

- Dash and choke support bracket holes

- Repaired

- Small cracks in steering column support bracket

- Svempas Paintshop

- Slotted raised countersunk screws as original early cars

- The same slotted heads for bonnet prop rod support

- Slotted raised countersunk screws for support pillar bracket.

- Slotted flat countersunk screws as original

- These screws shall be sprayed over to achieve the correct factory look

- Phillips head screws as original

- Small screws attaches shroud to body

- Pop rivets

- Rear end waiting for sanding

- After final sanding, the body will be dismantled again

- To be sanded prior to painting

- Body assembled for last finishing

- Insulation strips

- Solid rivets on rear skirt

- Solid riveting of the rear shroud as original

- Front cockpit

- Rear deck and gearbox tunnel extension

- Rear inner wing

- Boot area

- Painted chassis

- Healey Grey. On this car Ice Blue Metallic

- Roller rockers

- Head and rocker gear

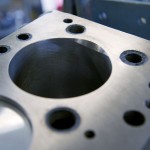

- Composite head gasket

- Double checking TDC as timing mark on pulley didn´t line up

- Aluminium sump

- Oil pump strainer

- Sump baffles

- New timing chain cover with modern lip seal

- Ready for timing chain cover

- Oil pump and flexible hose in the block

- New oil pump and drive shaft

- Cam timing

- Front plate gasket

- Rivets drilled out

- Engine no rivets

- Checking clearance with pocket

- Valve pocket

- Checking valve/block clearance

- Determining TDC

- Checking alignment of sprockets

- Camshaft and retaining plate

- Omega pistons

- First con rod and piston in place

- Drilled

- Racing big end shell

- Forged Omega pistons

- Steel con rods

- Denis Welch con rods by Arrow

- Hopefully no more leaks

- Housing and oil seal in place

- Housing with sealant

- Then the split oil seal

- It´s easier to put the spring in place first

- Guide for tapping the drilled holes

- Drilling for oil seal housing

- Aligning crank in order to drill for oil seal

- Adjusting block to be level

- Drilled holes in steel crank

- Beautiful crank by Denis Welch

- Assembly starts

- Extra oil return hole

- An extra oil escape hole was drilled for rear oil seal mod

- Removing damper the correct way

- After honing

- After honing

- Honing in order to enlarge by 0.03 mm

- Lasse made his own tool for enlarging main bearing housings

- Middle main bearing housing was to tight. Off to Lasse Tornblad, who without doubt is one of the most skilled men in the Classic Car repair business in Sweden.

- Testing for leaks

- Better standard oil seal on early steering boxes

- Done

- Worm located within the housing

- Ball cup

- Needs to be carefully assembled

- Putting the rivets back

- Outer column and housing mated with some sealing compound

- Cleaned housing

- Outer column and rivets

- Ready for assembly

- Cleaning steering rocker shaft

- After bearing cap has been torqued down and removed

- Plastigauge to be on the safe side

- Checking free play

- Checking the size

- New main bearing cap studs

- Checking for correct backlash

- Quality bearings for crown wheel carrier

- Skimmed flange surface and attached to bracket in order to torque down nut

- Truing coupling flange surface. Important as permitted deviation is only 0.02 mm.

- Checking pinion depth

- Calibrating dial indicator with gauge block

- Front bearing installed

- New quality bearings

- Pulling old tapered roller bearing off pinion

- New cylinder liners

- Chemically cleaned

- Engine block back from machine shop

- Diff housing

- Cleaned diff housing

- Finished gearbox assembly

- Adaptor plate

- Testing and adjusting

- Aligning the splines before mounting on the test bench

- NOS solenoid

- Front housing in place

- Operating pistons with new rings

- Pump body pressed in place

- Clutch and brake ring

- Planet carrier

- Uni directional clutch

- Torquing the nut

- Coupling flange with machined surface

- Clutch and carrier

- Tidying up the clutch linings

- Sliding clutch carrier

- rear assembly

- Annulus ready for the rear casing

- Backside of pin riveted

- Replaced with a new one

- One thrust pin was broken

- Early gauges shipped to Switzerland for complete overhaul

- Early gauges

- Finished gearbox waiting for the overdrive

- Release bearing

- Final assembly after tests

- Trying the gears with the lever

- Cover ready for box

- Assembling cover

- Trying the gears

- Bellhousing oilseal

- Forks in place

- Reaming 1st and 2nd shift fork

- All gears in place

- Assembling gears in casing

- Trying selector rods in casing

- Opening up layshaft steel thrust washer

- Back side of early steering wheel

- Early wheel restored

- Restored starter and dynamo

- Painted rear axle

- Healey Ic Blue metallic matched color samples

- Abutment collar

- Abutment washers

- Rear bearing in place on mainshaft

- Bearing mounted to input shaft

- Empty diff nose case

- Pinion with inner tapered bearing

- Chrown wheel removed exposing pinion

- Diff

- Pulling out diff bearing

- Core plug removed

- Oil pump

- Housing oil pump

- Accumulator housing and piston

- Removing accumulator housing and piston

- Empty rear housing

- Removing rear oil seal

- Annulus

- Extracted speedo pinion and housing

- Early type O/D annulus

- Early type strainer

- Early type strainers had this bolt fixing

- Disassembling overdrive

- Shortened

- Input shaft needs to be shortened by approx 14 mm, when used in a 100

- Third gear

- Needle roller for third gear

- First gear hub assembly

- Second gear

- New BJ8 mainshaft for straight cut gears

- Disassembling old mainshaft for parts

- Third gear Sebring 24 teeth, Tulip 25

- Casing and cover gearbox

- Sebring ratio straight cut gear set

- NOS wiper motor

- Complete wheel box

- Wheel box

- Wiper wheel box

- NOS wiper motor

- Handbrake mechanism

- Early type handbrake lever

- Original -53 flasher relay

- Fine surface

- Steering rocker shaft

- Zinc plated

- Zinc plated parts

- Joints caulked on the bottom

- Caulked joints

- All joints caulked

- Chassis in primer

- Wings and doors primed

- Front shroud in primer

- Rear shroud in primer

- Engine parts going to the balancing shop

- Finished

- Welded

- Parts needing repair

- Wirebrushed parts for zinc plating

- Correct brake pipe set by Mr Finespanner in the US

- More cleaned parts

- Starting to dismantle overdrive

- Correct American heat shield kit. Manufactured with support from Roger Moment.

- Parts for rechroming

- Parts to be wire brushed

- Wire brushed parts to be zinc plated

- Glass blasted parts

- Recored radiator. No fan guard on early cars

- Bracket for dash and choke

- Idler and steering box bodies

- One needed a helicoil

- Screws successfully removed

- Screen pillar

- Parts for rechroming

- Removing frame

- Parts for wire brushing and blasting

- Parts for glass blasting

- Radiator tanks will be straightened

- Early steering box

- Cleaned parts

- Two piece dash

- Glass blasted

- Only primer on back side

- Lots of holes to repair

- Looking for original paint, in vain

- Very poor original trafficator

- Cracked early type adjustable steering wheel

- Dashboard to be stripped from paint and restored

- Brake balance bar and two master cylinders for dual circuit brakes

- Clutch bracket and brake balance bar

- Welding clutch master cylinder bracket

- Practical deviation from original, hydraulic clutch

- Making small finishing adjustments on inner wing

- Adjustable column on very early 100´s

- Very early steering box

- Filling surplus holes

- Great shape

- Body work finished

- Rechromed with original satin finished slats

- Second hand OEM grille fitted. So much better than repro

- We can now start to imagine the final result

- Fits well after hard work

- Second repro grille fitted. The first one was impossible

- RH side looking fine

- Beginning to take its final shape

- Front lower shroud repair panel corrected after many hours of hard labor

- Anders Pettersson found what is believed to be the original bonnet skin of this car

- Ill fitting new lower shroud repair panel

- Poor lower front shroud

- Front shroud with poor old repairs

- Well fitting lower repair panel

- Ill fitting new rear wing. Needs lot of work

- High quality

- B-post

- Boot near completion

- Reinforced front lower wishbone mounting

- Reinforced rear lower wishbone mounting

- Left side being fitted

- Lots of work to fit new wings…

- New aluminum wing

- Boot floor welded

- Repaired shroud edge

- Fitting boot lid

- Repair to lower rear shroud

- Inner wing fitted

- Boot lid stay up support. Early type?

- Boot lid stay up support

- Heritage certificate says body #124. Stay support brackets says 134

- Early aluminum boot lid

- Rear chassis extensions welded in place

- Holes for bumper brackets had to be moved

- Battery access panel

- Work on the shroud has commenced

- Breakfast in Borås

- Fitting rear shroud

- Repaired door skin

- Door skin repair panel that fits

- Door frame repair panel that fits

- The boot is beginning to take shape

- All wishbone mountings were cracked

- Welded permanently in place

- Front shock plate

- Tunnel centered over gear lever

- Perfect fit after reaming

- Now have to be reamed

- Spring hanger bushes being pressed in place

- Spotwelding the rear tunnel to the rear bulkhead

- Fitting the gearbox tunnels

- Perfect front alignment, checked with solid bushings

- The metal master craftsman Hasse Syrén

- Engine and chassis

- Pedals and bracket fitted

- Gearbox and tunnel extension panel

- Gearbox mounting points

- Engine and gearbox temporarily fitted

- The inner wing seen from the boot

- Hasse fabricated a new rear inner wing

- Attachment point for bump stop

- Welding bump stop attachment

- Spring hanger. Rear right outrigger

- Spring hanger. Rear left outrigger

- Crossmember with spring hangers

- Reconditioned standard engine that will be rebuilt into race engine, since we unfortunately haven´t been able to source a good second hand block

- Lots of parts removed

- Chassis rails very good. Have been treated with Waxoyl

- New rear cross member

- Boot floor missing

- Boot floor removed

- Mock up gearbox and overdrive for aligning attachment points

- Cleaning gearbox parts

- Inner wing repair panel

- Repairing bump stop attachment

- Hasse in action

- Repaired inner wing piece

- Repairing inner wing bump stop attachment

- Inner wing repair panel

- Looking good

- Replaced firewall

- A-post bracing

- A-post bracing

- Footwells and A-posts

- Repairing rusty area of inner wing

- The front is almost finished

- Australian sheet metal is very well made

- Everything is coming together beautifully

- It´s a revelation to work with parts that fit

- Side panel that fits

- Side panels

- Everything fits without modifications

- Footwells in place

- High quality metal

- Complete footwell

- Footwell

- Rear outrigger and inner sill

- Complete inner sill

- Front floors

- Front floors

- Discarded metal

- New rear shroud repair panel

- New front shroud repair panel

- Ventilation duct

- Repaired rear inner wing

- Inner sill fitted

- Inner sill

- Trial fitting of rear bulkhead

- All new outriggers

- Outrigger with cut out for racing exhaust

- Repaired front wing. The corner will be shaped later

- New left front outrigger

- New rear left outrigger

- Lots of work

- Rear bulk head removed

- Removed front floor

- Airy

- Inner sill outriggers and floor removed

- Shock mount. Moving plate made of tool quality steel

- Preparing to measure correct angles

- Bottom part has to be removed in order to replace cross member. Now restored

- Shock tower restored with bottom part

- High quality adjustable shock mount

- Shocker mount removed

- Rear cross member has to be replaced

- Gas welding again

- Gas welded

- No rust inside whatsoever thanks to early waxoyl treatment

- Main chassis rail in surprisingly good condition

- Mounted in rotisserie

- High quality crossmember attached

- More gaswelds

- Incorrect floor

- Crude gas welds

- Incorrect boot floor

- Some crude repairs from the seventies

- Prepared for new crossmember

- Front cross member removed

- The majority of new sheet metal parts have arrived.

- Everything has been sodium bicarbonate blasted

- Good door!

- Looking good!

- The left floor which is original has the very early pressing

- Front of chassis after blasting

- The chassis has been blasted, which didn´t reveal any big horrors

- The boot

- Looking quite good, especially considering its age and that it has been in Sweden all of its life

- The car was found in the city of Boras

- The car is in a surprisingly good shape, despite its looks

- The car was disassembled for restoration in the early nineties but has since been standing

- Henrik in action on the Travering during Prix Maritim 1982.

- Henrik at speed during the Norrköping GP in -86 or -87

- Norrköping GP. Stirling Moss liked the car and came by for a chat about Healeys

- Prix Maritim 1982, waiting to start a special stage. Day one consisted of special stages, day two was on the Travering track.

- Henrik on the way home from the Prix Maritim.

- 100M-plaque sits on the dash instead of the cold-air box.

- Prix Maritim, Henrik fitting Brooklands screens …

- … and tightening the screws.

- 2 inch carbs.

- Prix Maritim, ready for action …

- … sheepskin seat cover in place.

- Mats Svanberg and Henrik Engström, in the background, preparing their cars for the Prix Maritim.

- Kjell has taken very good care of Mats old BJ7

- This is what Mats old car looks like today

- Mats Svanbergs black and white BJ7 is now red and owned by Kjell Bengtsson in Sundsvall.

- A younger version of Mats Svanberg in black. He is only getting prettier for each year.

- Henrik with his prize from the Travering 1982.

- Outside the hotel in 1982.

- Nice company in the Prix Maritim, a Ferrari 250 Lusso and a Bugatti.

- Henrik preparing for the Norrköping GP.

- The 100 sharing Henrik’s garage with a Fiat-powered Formula Junior.

- Henrik and family loading the car.

- Camping 1980 style

- The start at Travering Raceway in 1982.

- Travering Raceway, the four cars started with a few seconds in between.

- Entering the start-finish straight at the Travering Raceway.

- Then owner Henrik Engström ready for the Prix Maritim 1982.

- Front page of Teknikens Värld no 22 1953

- Skarpnäck Raceway September 1953

- Raymond on the right with movie director Roberto Rosselini. In the middle Errol Flynn??!

- After setting ice racing record at lake Varpen

- Saluting girl 1956

- Preparations before Hedemora GP 1954

- Raymond touring with his son